Get Gephardt: Need your car repaired? Be prepared to wait

Nov 7, 2022, 10:20 PM | Updated: 10:56 pm

LINDON, Utah — If you had to, how long could you wait while your car gets fixed? Days? Weeks? How about months? That is how long a global parts shortage is keeping many cars off the road, even for relatively simple repairs.

And the frustration isn’t just being felt by drivers, as auto body repair shops and mechanics face huge backlogs.

Waiting months for a simple fix

Grant Clark’s daughter’s Volkswagen spun out on ice last December and slid into a curb.

“Not a lot of damage, but it did cause enough for the airbags to go off,” Clark said.

As far as accidents go, it was very minor. Not nearly enough for insurance to total the car. Instead, it was brought to a Lindon body shop to get the deployed airbags replaced. It has sat there for close to a year, with Volkswagen telling Clark that they do not have the parts.

“There is just no end in sight,” Clark said.

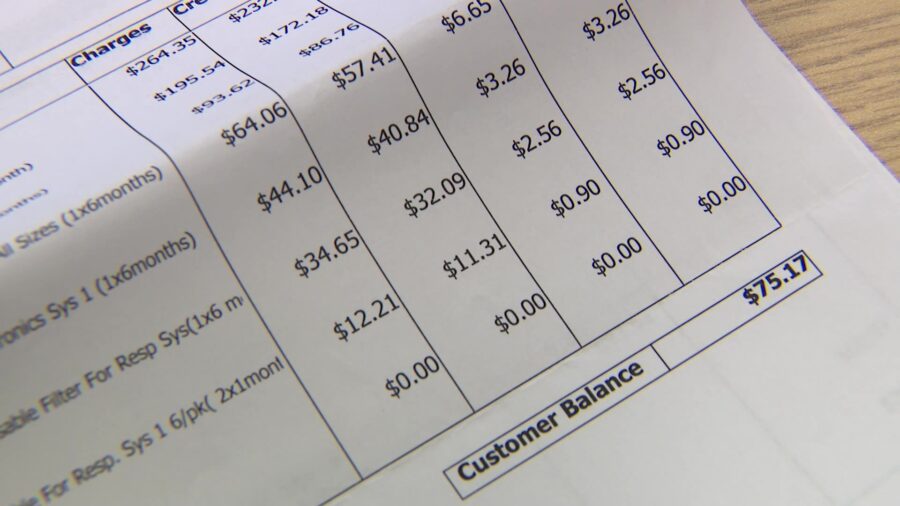

Grant Clark says his damaged Volkswagen has been sitting at a repair shop for almost a year, waiting on replacement airbags from the car maker.

He believes he would have been better off if the accident had been worse.

“If it would have been totaled out, they would have just given me the value of the car and I would have gone on and gotten a different car.”

Clark said he understands there are supply chain issues, but he wishes the carmaker would shift at least some of its efforts to supporting their current customers.

“They’re making brand new cars,” he said. “They offered to sell me a new car, but they can’t fix my old car.”

So, what does Volkswagen have to say about this? Nothing to me. I reached out to two Volkswagen executives in Virginia and heard nothing back. I then reached out to multiple Volkswagen executives at the company’s headquarters in Germany. Still nothing. It wasn’t a matter of my messages not getting through, because I did get one acknowledgment: a bounce back from one of the execs saying he was on paternity leave.

But not enough parts keeping cars off the roads is not just a Volkswagen issue.

Mechanics are equally frustrated

At Steve’s Automotive Specialists in Sandy, CEO Jeremy Smith said it is tough all over.

“We are sitting on 11 cars that we are waiting for parts on,” Smith said. “Some of those, we’re expecting the parts within weeks. We do have one or two that we’ve been waiting for more than 60 days.”

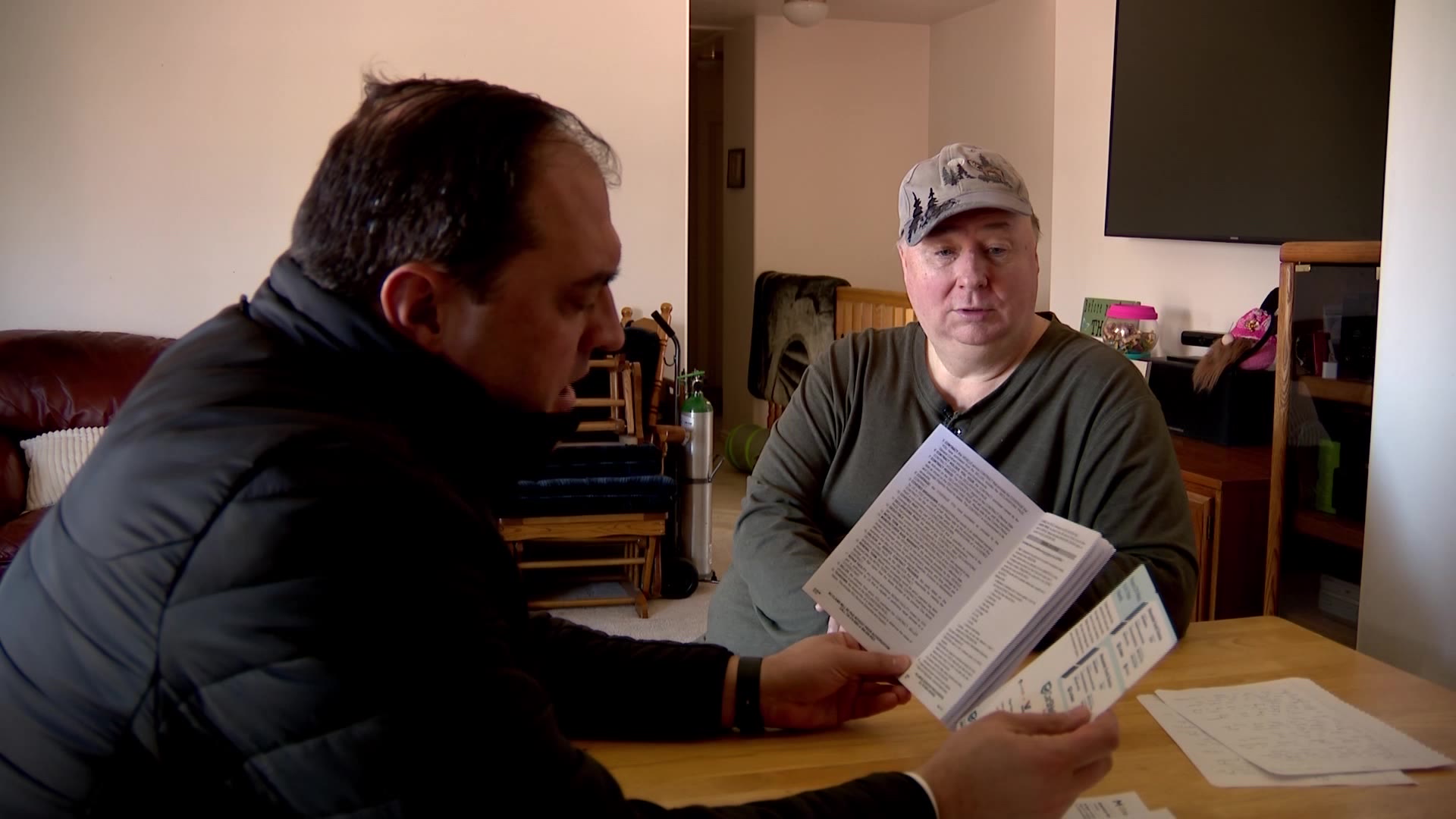

Jeremy Smith of Steve’s Automotive Specialists tells KSL’s Matt Gephardt they’ve had several cars on hold for weeks, and a few still waiting for parts after 60 days.

Smith just got back from an automotive conference in Texas where he said mechanics and body repair technicians were all lamenting the same problem.

“There’s parts of the country where apparently they’ve got lots filled with thousands of cars they can’t get back on the road from just rental companies,” he explained, “because they can’t get the parts for them.”

Car parts largely come out of China, and with China still largely on lockdown, trying to quash the pandemic, it has made getting parts next to impossible.

The solution?

“Oh, boy, make more stuff in America,” Smith answered. “I mean, that’s going be the first thing I’m going to throw out there. I mean, we aren’t manufacturing anything here anymore.”

A global parts shortage is backing up work at service centers across the country as they are forced to wait on parts from overseas manufacturers.

Supply chain issues

These supply chain issues aren’t just impacting people who need parts for their current cars — it is also impacting new cars. According to a report from J.D. Power, “new vehicle quality has notably declined” and the new car industry “experienced an 11% increase in problems” compared to last year because of supply chain issues.

“Really what I want is just the car to be fixed,” said Clark, who still has no timetable on when his Volkswagen will be back on the road.

“They say it’s on backorder. That means it could come in next week,” he said. Or, “It could be next year.”

The dashboard of Grant Clark’s Volkswagen has been disassembled for nearly a year as the repair shop waits on new airbags from the manufacturer.

There has been a push for more car parts to be made in America since the pandemic lifted the curtain on how reliant our country has become on manufacturers from other places. The most notable example, perhaps, is an $1.8 billion plant being built in Indiana where they will make microchips for cars.